Maintenance

About maintenance parts (purchase and replacement of mortars, pestle and others)

We sell mortars and pestle of Ishikawa type stirring and crushing machine, as well as safety covers, scraping boards (plucking sticks), and pestle as maintenance parts. We especially recommend purchasing the mortars and pestle as a spare in case of sudden damage.

In addition, mechanical parts such as gears and shafts for machines, and original genuine parts of Ishikawa type stirring and crushing machines such as pestle rods, pestle springs, and die parts such as clasp, and machines such as belts, motors, vacuum pumps, etc. We also sell parts.

*By accumulating the manufacturing number, customer name of purchase and history as a database, we enable more accurate and efficient support.

When purchasing or inquiring about maintenance parts, please confirm the model (model name) and serial number.

How to check the model (model name)/serial number of your Ishikawa type machine

The model (model name)/serial number is printed on the (green) metal plate attached to the machine frame.

How to check the model (model name)/serial number of your Ishikawa type machine

The mortars and pestle will gradually wear out, depending on the usage time of the customer's machine and the processing material.

The porcelain mortar wears off due to abrasion with the tip of the pestle, and may be suddenly cracked by a slight shock during processing. In addition, abrasion of the tip may change the time required for stirring and crushing and the processing results. It is recommended to bring a spare mortars and pestle to stabilize the quality of the stirring and crushing treatment result and to prevent the machine from stopping due to sudden damage.

Types of pestle and mortars

| Types of mortars | Type of Pestle | |

| Cylinder of pestle | Top of pestle | |

| Porcelain mortar | Porcelain (Cylinder and top integrated) | |

| Cylindrical gun metal |

Wooden pestle top Teflon pestle top |

|

| Stainless cylinder | ||

| Stone mortar | Cylindrical gun metal | |

| Stainless cylinder | ||

| Gun metal mortar | Cylindrical gun metal | |

| Stainless mortar | Stainless cylinder | |

Explanation of mortar for each material

Porcelain mortar

A mortar is a basin made of mainly SiO2, which possibly to crash the hard products. It possesses outstanding chemical resistance. Since this is made of porcelain, this is a suitable for the process such as semi-conductor related process that wants extremely avoid contaminating with the metal powder.

Stone mortar

The stone mortar is made of granite. This consists of the crystallized minerals, such as potash feldspar, quartz, plagioclase, and mica. The friction on the mortar surface is lower than the porcelain one, so stone mortar has better efficiency for pestle to grab the ingredients. It also slightly cools the processed ingredients. un metal mortar

It has outstanding thermal conductivity and corrosion resistance.

Gun metal mortar

It has excellent thermal conductivity and good corrosion resistance.

Stainless mortar

It has excellent corrosion resistance.

Cast iron mortar

It has the same thermal conductivity as the gunmetal mortar, but it is slightly inexpensive.

Agate mortar

It has the same hardness as porcelain, but it has abrasion resistance. It is suitable to use as an apparatus of analytical purposes.

Alumina mortar

It has high hardness and abrasion resistance; therefore, it is suitable to crush hard ingredients.

Tungsten carbide mortar

It has the most outstanding abrasion resistance of our products. It is suitable to use as an apparatus of analytical purposes.

About pestle replacement and purchase

When ordering pestle maintenance parts, the number (pestle size), pestle number, type of pestle (material of pestle tube and pestle tip)

For porcelain pestle, please check standard type, dustproof type or T type*. The confirmation method is as follows. If you have any questions, please check the serial number and model before contacting us.

*The T type is a type that allows you to replace the internal parts of the pestle yourself.

How to check the pestle number

The pestle number can be identified by the number of lines on the top of the pestle.

Mount the pestle at the box pestle mounting hole number that is the same as the pestle number.

(No. 1 pestle is box pestle mounting hole No. 1 and No. 2 punch is box pestle mounting hole No. 2 and 3)

【Top of pestle】

【Mounting position of pestle】

Similarly, the 3rd pestle is engraved with 3 lines and the 4th pestle is cut with 4 lines.

Type of pestles and tips(tops)

Material: pestles/tips(tops)

1=stainless/agate

2=iron one piece

3=stainless one piece

4=gun metal/wood

5=stainless/porcelain

6=stainless/wood

7=stainless/Teflon

8=Porcelain one piece

Types of porcelain pestles and how to identify them

| Type | Basic structure | Maintenance for inside of pestle | Basic structure | ||||

| Disassembly | Y/N Required tools | Notes | Mouthpiece | Oil seal(Rubber made) | |||

| Dust-proof | Oil seal installed type for mash-crushing of powers | Y | Vise, etc. | Possible to disassemble with the specified tools.Basically overhauling at Ishikawa Kojo | Possible to use long-term with regularly maintenance | 1 piece | Y |

| T type | Easy to disassemble for maintenance |

Y |

Screwdriver | Possible to disassemble/assemble with screwdriver | Suitable for high frequency of maintenance | 2 pieces | N |

| Standard | Simple structure, relatively inexpensive |

N |

|

Not applied for already fixed | One-time use after use | 1 piece | N |

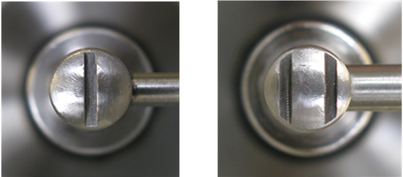

If XX-T and T" are displayed on the pestle, it is a dustproof pestle or T-type pestle. Refer to the photo for identification of the dustproof pestle or T-type pestle.

Dustproof pestle & T type pestle

Check the size and material when replacing the porcelain mortar. If you have any questions, please contact us after confirming the model and serial number for your machine of Ishikawa type.

If the porcelain mortar is replaced, set the mortar called "centering" on the machine.

Position adjustment is required.

-Porcelain bowls are pottery, and there are individual differences in shape and size.

Porcelain mortar size check method

The size of the porcelain mortar is marked on the front of the mortar.

*For metal pots and alumina mortars other than porcelain mortars, the number is not displayed, so ask for the model (model name) and serial number, and check the material and model of the mortar by collating with our database.

About the purchase of scraping board and scraper

If you are unsure about your scraping board and scraper.

Please contact us after confirming the model (model name) and serial number.

Maintenance parts for desktop machines (D series)

(The mortar and pestle are the same for each machine size of the Ishikawa type stirring and crushing machine.)

If you have any questions, please contact us after confirming the model (model name) and serial number.

-It is also possible to mount a stone mill (granite) and a stainless steel pestle (wooden top or Teflon top) on the tabletop machine (D series).

The stone mill has the effect of suppressing frictional heat. It can be mashed for the development of foodstuffs and the production of small quantities without impairing the original flavor and aroma of the ingredients.

*A stone mill can be installed from D16S to D22S.

About maintenance parts (mortar, pestle) for AGA/AGB/AGZ

AGX type mortar and pestle are exclusive. We also offer purchase as a set with a bowl holder and polishing service for agate bowls.

The combination of mortars and pestle tops

1=Alumina/Alumina

2=agata/agata

3=Tungsten carbide

Please note

When purchasing mortar, pestle, mechanical parts and pestle parts of the machine

Please contact us after confirming the machine type (model name) and serial number.

For customers who wish to repair or purchase maintenance parts

By accumulating the manufacturing number, customer name of purchase and history as a database, we enable even more accurate and efficient support.

Therefore, when contacting us, please enter "company name, department name, name, phone number, e-mail address", "model name", "serial number", or "parts" when purchasing parts. Please contact us including "parts name and its quantity".

We will check the content of your inquiry and contact you.

If the above information cannot be confirmed or does not match, we may not be able to trade.